◆ 光纤激光技术与数字控制技术的完美融合,代表着最先进的激光切割水平;

Integration of fiber laser and digital controlling, which represents the most advanced technology of laser cutting.

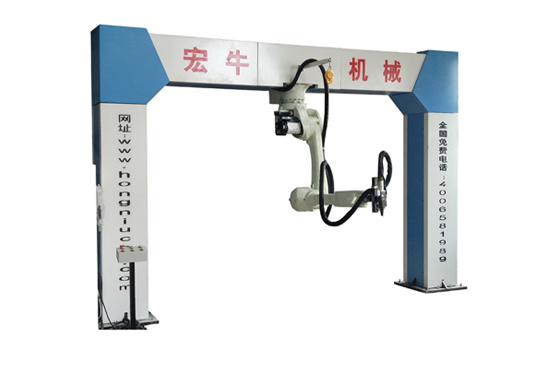

◆ 机械结构采用进口机械手,六轴联动,将激光束引导装置完全集成在机器人手臂中,将稳定的激光和运动的机器人手臂的优势相结合.可实现三维空间内任意曲线和特定曲线的加工,操控方便,智能化程度高,大大减少了周期时间,保证了设备的高速运行、高精度及高可靠性。

This machine adopts imported manipulator, 6 axis. Laser beam guiding device is fully integrated in robot arm which combination the advantage of stable laser and moving robot arm. It can realize arbitrary and special curves processing in 3D space. Easy to operate, higher automation, less cycle time ensure the machine’s fast moving, high precision and reliability.

◆ 工业机器人与光纤激光的组合进行加工,使加工工艺一次完成,切口整齐无需后道工艺再处理,大缩短了工艺流程,降低了人工成本和模具费用的投入,也提高了产品档次和附加值。

The combination of industrial robot and fiber laser complete the processing once for all. The cutting edge is tidy.so second processing is not needed. This will greatly shorten the process line and reduce the cost of labor and tooling. As well as improving the products grade and added value.